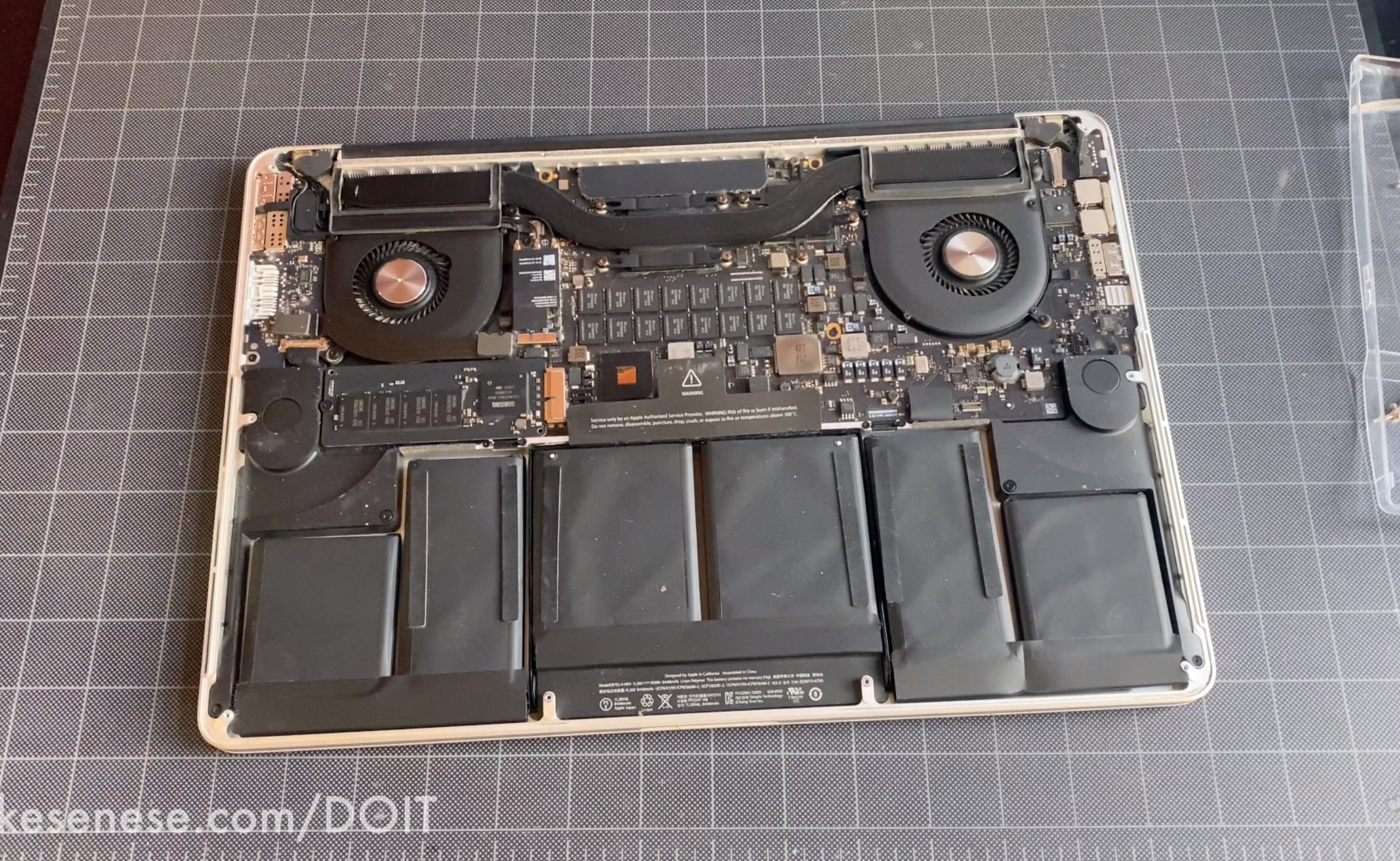

How to Change a Macbook Pro battery Quickly and Easily With Kite String

With kite string, fingernail polish, and careful computer positioning, you can sidestep the challenging disassembly to remove your depleted MacBook battery.

Fun with Shoe-Goo: Reinforcing Skate Sneakers With Leather Scraps

Growing up one of the tricks we’d do to protect our sneakers would be cutting the suede or leather tongue off an old shoe and glueing it to the spot where you’d get a hole from ollieing. It worked incredibly well! The Vision Street…

Wonderfully Simple Joby Gorillapod Broken Leg Fix

It’s pretty great what you can do with simple heat shrink tubing!

How I Fixed My Shaking iPhone 6S Plus Rear Camera

If your iPhone camera is shaking you can buy a cheap replacement camera and fix it yourself, despite Apple saying it is non-serviceable.

Make a Skull from your CT Scan

Call the radiology or imaging department and ask them for your data, then process it in easy software and send it to the printer. Easy!

Catapult madness at the Craftsman Makecation

This is the story of the time I built a trebuchet and launched water balloons over the the Lake Arrowhead lodge.

This beer-powered Slug trap Totally Works

Where I live, we seem to get an abundance of slugs. I let the trails across the driveway and garage door pass, but once they started chewing through all the seedlings in the garden, I decided I needed to do some population control. There…

Oversized Halloween Witch Silhouette

Last Halloween my wife showed me a Halloween lawn ornament she liked and asked if I could make one like it. Challenge accepted. I began by searching on the internet for witch silhouettes. I found an image of one that looked particularly spooky and…

Video Roundup: More DIY Skate Ramps

It’s been a while since I’ve run through the resources for building skate ramps that exist online. And with so many now appearing on Youtube, I’ll focus this post on those plans and builds that appear there in video form. Let me know if…

Quick Fix: Broken Laundry Rack

Our favorite way to dry our clothes broke, so I put the 3D printer to use to bring it back.