Catapult madness at the Craftsman Makecation

This is the story of the time I built a trebuchet and launched water balloons over the the Lake Arrowhead lodge.

Oversized Halloween Witch Silhouette

Last Halloween my wife showed me a Halloween lawn ornament she liked and asked if I could make one like it. Challenge accepted. I began by searching on the internet for witch silhouettes. I found an image of one that looked particularly spooky and…

Fixing a Broken Power Plug on the MicroDrone 2.0

The Microdrone 2.0 is a pretty sweet little quadcopter. Surprisingly stable and cautiously responsive for its small size, it’s also able to whip around outdoors in a bit of a breeze, high in the sky. The unit I have, however, has an overly tight socket…

Never Shop at Harbor Freight Without a Coupon – Links to their best deals

More Harbor Freight online coupons, to save you a ton of money on their weirdly low tool prices – sometimes concerningly low (remember, “you get what you pay for”). Take advantage by printing the best ones before you drive to your nearest location, or have…

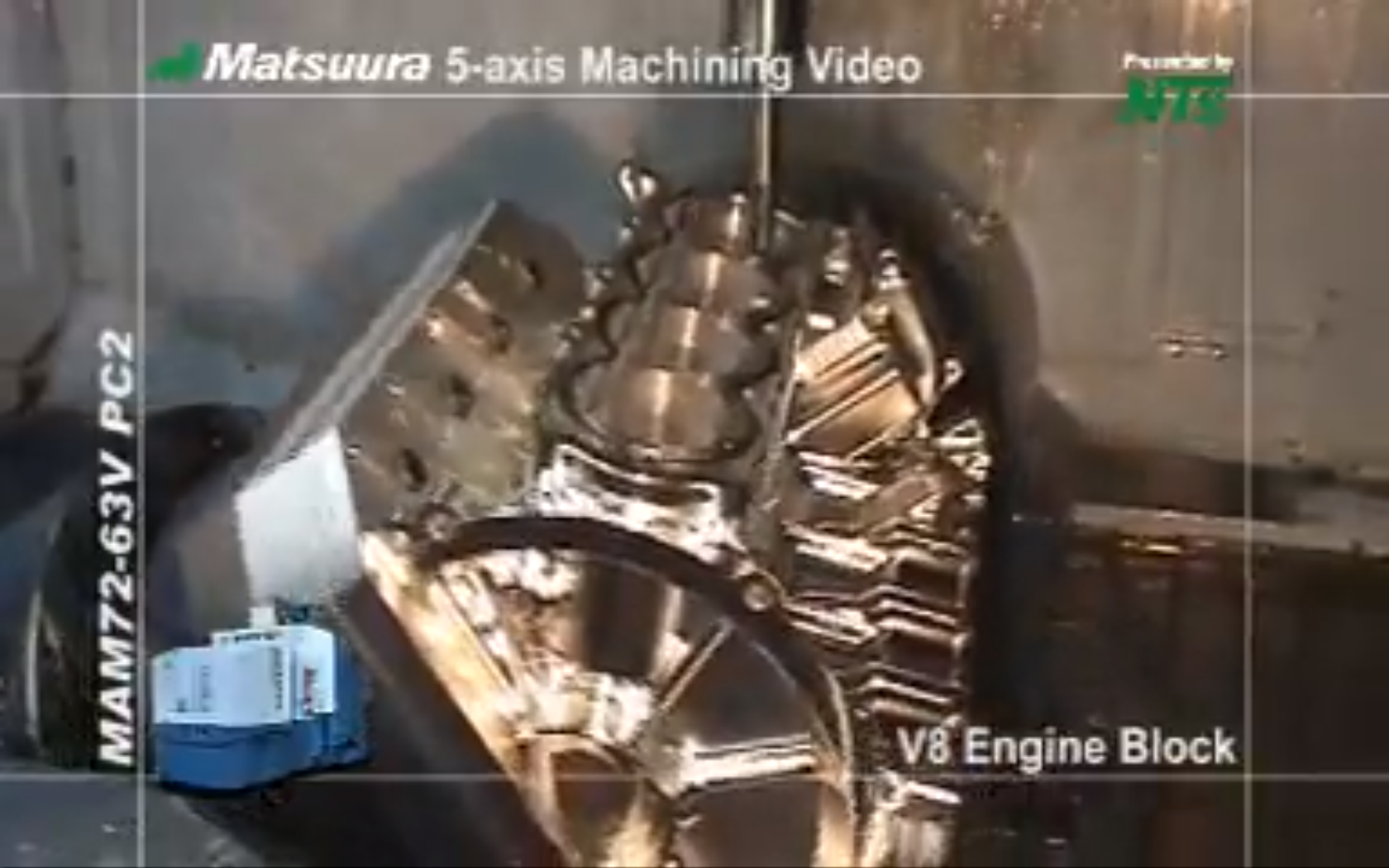

Video Fun: V8 Engine Block Machined From Solid Aluminum on a 5-Axis CNC Mill

Just a little something to fall asleep to tonight.

DIY Motorized Router Table Lift Mechanism and Two Other Innovative Router Tables

A router is a versatile and useful tool, although a pretty crazy one too. It’s a compact, high-powered motor that holds a narrow cylindrical blade (“bit”), spinning at ultra-high speeds with massive force. Routers are used for ornamental design work (look at the recessed…