Steel Drums Made From Discarded Barrels

Sometime around 30 years ago, a segment on Sesame Street left an impression on me. In the scene, a few kids rolled a steel barrel to a man who hammers away on it and creates a steel drum, then they play a Caribbean-style tune on it.

I don’t see or hear steel drums often these days, but whenever I do, I instantly think of that segment. Are steel drums really made from discarded barrels that kids find in fields? Is it really that simple to make one? After some quick research, it seems the answer is yes and no…

You can see in the Sesame Street video (which itself is an interesting time capsule of 1981 New York), the drum making has been abridged to fit in the short time constraints of the show. But watch the following video – the drum is created by pounding a heavy weight (looks like lead ball) against the bottom of the barrel, denting it inwards. It’s then further refined and smoothed with taps of a hammer.

The DIY Cheapo Thermocam

While filming Catch It Keep It and Rock and Roll Acid Test, we had a couple segments that were very heat-dependent. The scenes needed a way to show the temperature and changes of the stuff we were researching (one scene, frozen steaks; another scene, women’s panties–I know, classy). We used Flir B50 thermal imaging cameras which capture a real-time, “Predator”-style visualization of the temperatures of the area it is pointed at. I didn’t realize at the time that these cameras cost thousands of dollars.

If you want to recreate the same effect but don’t need the immediate, live visual, here’s an easy build to create your own at a fraction of the cost, using a basic infrared thermometer, a webcam, and an arduino.

The whole how-to can be found here.

Partlist

From sparkfun.com:

– Pan/Tilt Bracket $5.95

– Servo – Small $8.95

– Servo – Medium $10.95

– optional: Laser Card Module – Red $7.95

– optional: ProtoBoard – Square 1″ Double Sided – $2.50

From futureelectronics.com:

– MLX90614ESF-DCI $34.64

– 2 x 4.7kOhm Resistor $0.06

From seeedstudio.com

– Harness for Arduino/Seeeduino kit $6.50

– Seeeduino V2.21 (Atmega 168P) $19.00 (or any other Arduino)

From amazon.com (or another retailer):

– Microsoft LifeCam VX-700 $7.49 (as far as you dont’t have a comparable webcam yet)

What you also need but most likely already have at home:

Cables, Soldering Iron, Wire Cutter, Heat Shrink Tube, Tape, USB Cable for Arduino

All the parts in this list cost together 104$, but if you already have an arduino or a webcam for example it’s a lot cheaper

Wooden Honeycomb Surfboard – Taking board making to the next level

Surfboard making of the foam variety is one of those arts that really appeals to a select few. Most surf fanatics tend to live in coastal areas, and at that, the largest concentrations are those in favorable climates. But there’s something about wooden surfboard making that seems to extend beyond this population, impressing people by the sheer beauty and craftsmanship of the art.

These wooden boards are most often hollow constructions with an internal spine-and-rib-like framework. Carefully milled and planed wood planks are layered and shaped into the elegant curves that are typically carved from foam blocks on conventional boards. Depending on the material, the finished product is then laminated, or not.

There are some amazing artists making these wooden boards – check out Danny Hess and Grain Surfboards for two examples that you can find and purchase. But New Zealand computer engineer post grad Mike Grobelny has stepped the game up with his latest project, a CAD designed, CNC-routered honeycomb surfboard. This takes things to an awesome new level.

With a workshop that would make almost anyone envious, Mike graciously captured the entire build process in time lapse, from digital all the way to first-person view of the board in action.

Hard to not get inspired by footage like this. And remember, you can never have too many clamps.

Twelve Awesome Commodore 64 Hacks and Projects, and a Gallery of Classic C64 Game Discs

I recently visited my folks and as usual, spent most of my late evenings there digging through all my childhood belongings. Comic books, skateboard parts, Guitar Player magazines. And my Commodore 64. Flipping through all the old floppy discs and remembering the countless hours playing games, I started to think about what the C64 community is up to nowadays. Turns out, quite a bit…

Also, check out the scans of my old disks and game boxes at the end of the post. I put a batch from my Amiga 1000 in there too. Anything that you remember from growing up?

====================

C64 Laptop: Take the guts from your Commodore, an LCD screen, and an SD storage system designed on the DTV-64 platform (more about that below), put it all together in a CNC-made custom laptop case, and you’ve got something that would make everyone jealous of you while taking notes in class… in 1986. This is the “what if” laptop that could have been, if laptops were around in the mid-80s.

How To Disassemble the new Nikon D7000 DSLR

Nikon’s new D7000 is an awesome camera full of great technology. But what’s on the inside? The Thai site vimoncamera.com takes it upon themselves to pull the case apart piece by piece to show the innards for us to all enjoy.

One thing that stands out to me in the video is that electric screwdriver for those tiny precise screws – I’ve gotta get one of those.

(found this video on Nikonrumors.com btw. Great site!)

Watch Beginners Shape and Glass Surfboards To Learn From Their Mistakes

All surfers begin to contemplate building their own board at some point. Maybe it begins on a day of slow rolling waves, while the long boarders take all the rides a hundred yards behind the one guy on a shortboard. Or while watching the segment in Picaresque when the dudes strip that thriftstore board and reshape it into something sleek and fun. Or perhaps, like Luke Skywalker, you just feel one doesn’t become a jedi knight until he/she builds their own lightsaber.

No matter the reason, there are some great resources out there for the aspiring board builder. Online, check the forums on Swaylocks for years of discussions on people’s foam creations. Retailers like Foam-EZ sell all the materials and tools needed to build any board imaginable. And you can buy DVDs or watch an unlimited amount of Youtube clips of people explaining how to round the rails and so forth.

The first look at a blank block of foam waiting to be shaped can be overwhelming. Smooth, consistent, and equally even contours are a real art. And once a board is shaped satisfactorily, it is said that fiberglassing it is even trickier. So what is the best way for a beginner to learn how to do this?

Stephen Pirsch has answered this in a cool way. Rather than showing yet another video of expert shapers effortlessly carve and epoxy a new board, he’s created a video for beginners to watch other beginners fumble through the process, see the mistakes they make and the adjustments needed to correct them. One of the best initial videos I’ve ever peeked at – this is a brilliant concept.

Steve emphasizes that you use that knowledge to shape and glass your own small sample piece of foam. Do this before diving into any major board project of your own and your outcome will much pain-free.

Check out Steve’s site for more very insightful info on making your first board — the “tips” and “misconceptions” sections in particular have super useful notes, but the whole thing is a goldmine.

1958 Land Rover Series II and Defender 90 Rebuild Timelapse Videos – Two of the Best 4x4s Ever Getting Assembled

In case you didn’t know, I’m a classic Land Rover nut. Their rugged, no-frills style matches everything I like in life. Go-anywhere badassery, marching through deserts and over mountains. Or even better, desert mountains.

After my brother-in-law Steve got me bit by the LR bug, I found and bought a 1973 Series III in need of a little TLC and promptly dismantled it to get it back into “safe” running condition. That truck took me through the Baja desert, into the Arizona highlands, and on a very amazing slow-paced cross-country trek (a max range of less than 200 miles per tank combined with cruising speeds around 50mph kept me connected with small-town locals for a couple weeks).

Nowadays, my Land Rover is our beach vehicle in Rhode Island. Not being able to tinker on it regularly, I find myself watching videos of other people working on their trucks. Here are two batches of timelapse rebuilds and assemblies – the first, a 1958 Series II, the second, a Defender 90 built ground up, done by one dude alone! Enjoy.

Video: From Steel – Custom Steel Bicycle Fabrication

Another great documentary from Michael Evans (who shot the awesome video “Naturally Risen,” about Una Pizza Napoletana’s Anthony Mangieri). Watch as master bicycle maker Sean Walling expertly glides from machine to machine, cutting, grinding, and welding his way towards a gorgeous, custom steel frame beauty. I took some notes from this – especially the way he uses those hole saws to mate up the tubes.

Sean Walling, owner of Soulcraft, builds top notch custom steel bicycle frames. This short film documents Sean’s fabrication methods: a well choreographed dance of experience and muscle memory producing a seemingly effortless ode to process.

From Steel: invites the viewer into Sean’s machine shop for an up close and personal look at the work that results in yet another awesome Soulcraft.

Musical score provided by the internationally praised duo, Mattson 2. Courtesy of Galaxia Records.

Directed by: Michael John Evans: michaeljohnevans.com

Starring: Sean Walling: soulcraftbikes.com

Music by: The Mattson 2: mattson2.com

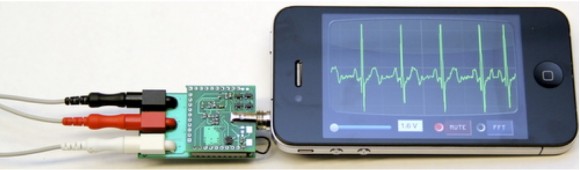

HiJack Lets You Interface With The iPhone Through the Headphone Jack

As computers progress, get smaller, become more powerful, the peripherals that we used to stack next to our desktop machines have begun to disappear. Modems, various types of disc drives, printers and scanners – all are now internalized with 3G connections, Library of Congress-sized storage, and camera/email/fax/e-reader capabilities.

The peripheral is now primarily a specialized piece of gear that records specific external signals – audio signals (for music recording), physiologic impulses (heart rate meters) and electronic signals. With devices like the iPhone having a single and unique port (and Apple having a costly licensing fee to use their connector), the development for new peripherals is handicapped.

And that’s why things like HiJack are so awesome. Utilizing the iPhone’s headphone jack, the 1-square inch connector is able to draw power from and interact with the iPhone. As of now, there are four devices built and programmed: a 3-cable EKG monitor, a soil moisture meter, a unit with temperature/humidity/motion and more sensors, and a breadboard for quick development of new devices.

What’s cooler is that the developers at the University of Michigan want you to get involved. From the HiJack site:

If you are interested in getting a HiJack board for your own project, then please send us a short (1 page) proposal of your project idea. The project requirements:

- Phone and HiJack code must be made available under an Open Source license (BSD-style prefered).

- We are allowed to link to your project from this website and/or include a picture of your project in the photo gallery.

We currently have 20 HiJacks available to give away. Depending on your project, we can also provide you with a programmer and a breakout board.

Please email your project proposal to hijack.project@gmail.com. in PDF format, and don’t forget to put your physical address and email on the top of your summary page.

Notes, Tips, and Recipe from my Birthday Pizza Cookout

For the past five years, I’ve had an annual pizza party for my birthday each January. It’s my excuse to get to cook as many pizzas as possible at one time, to test my pizza-making skills, to try to bring the best I’m able to bring for that year. Last night was the latest, and by my measurements, were the best pizzas I’ve made by far.

Here are my notes and recap.

I prepped two batches of dough: 6lbs using Trader Joe’s all-purpose flour, and 24oz using Caputo “Tipo 00” imported Italian flour (the standard that the top Neapolitan pizzerias use). The Trader Joe’s dough was made two days earlier, while the Caputo was made very early the morning of the party. I’ll get to details later, but here’s a spoiler: the Caputo did NOT work well.

For each batch, I used 65.5% hydration, following the A16 pizza dough recipe (the 6lb. quantities in parenthesis):

Flour: 100% (53.93oz)

Water: 65% (35.31oz)

Salt: 3.5% (1.9oz)

Yeast: 9% (4.86oz) (my sourdough starter yeast is about 100% hydration)

And as a kick-start, I added a pinch of dry active yeast to the mix (3/4 teaspoon to the Trader Joe’s, 1/4 to the Caputo). I’ve found that the starter yeast takes a bit longer to rise, so this helps make sure things are ready. Otherwise, I might as well just send everyone home.