Q&A With Joey Hudy, 14 Year Old Maker of the White House Marshmallow Cannon

14 year old Joe Hudy has been having fun. From promoting science at Maker Faires to shooting marshmallows with the President at the White House, he’s the embodiment of STEM education effectively motivating a new generation about science and engineering, while showing how it…

That Time I Shot a Pumpkin Thief With a Pumpkin Cannon (no, not really)

About a year and a half ago I helped some producer friends shoot a “punkin chunkin” themed segment of a popular cable TV show. I had initially talked with them about building a catapult for the scene, but they were able to locate a…

Palm-Sized Print and Cut Paper Trebuchet

Paper Trebuchet — a fun project for you projectile fans. Kill some time at work by printing the template, cutting it out, and folding it up. Then lay siege to your coworker’s sharpie collection. This isn’t a traditional trebuchet in that it doesn’t use…

Tuning A Trebuchet For Maximum Distance – A Look at the Components and Variables

Here are some notes on adjusting your trebuchet or catapult to help maximize the distance it will launch an object. Happy flingin’! ======================== Catapults and trebuchets originated more than 2000 years ago, and over time became highly sophisticated machines that represented the pinnacle of…

Trebuchet Roundup: Eight Online Plans Reviewed For Building Your Own

It’s autumn again. Such a wonderful time of year. Cider, hay rides, freshly bought school supplies. And launching things far through the air with catapults and trebuchets. This year, instead of being a mere catapult observer, why not build your own? Building a basic…

Make Your Own Cardboard Medieval Trebuchet

Do you want to launch a softball 50-60 feet without having to get down and dirty cutting wood, metal, and using power tools? Here’s an easy way to build a fairly sizeable trebuchet out of cardboard and a few other basic materials. For this…

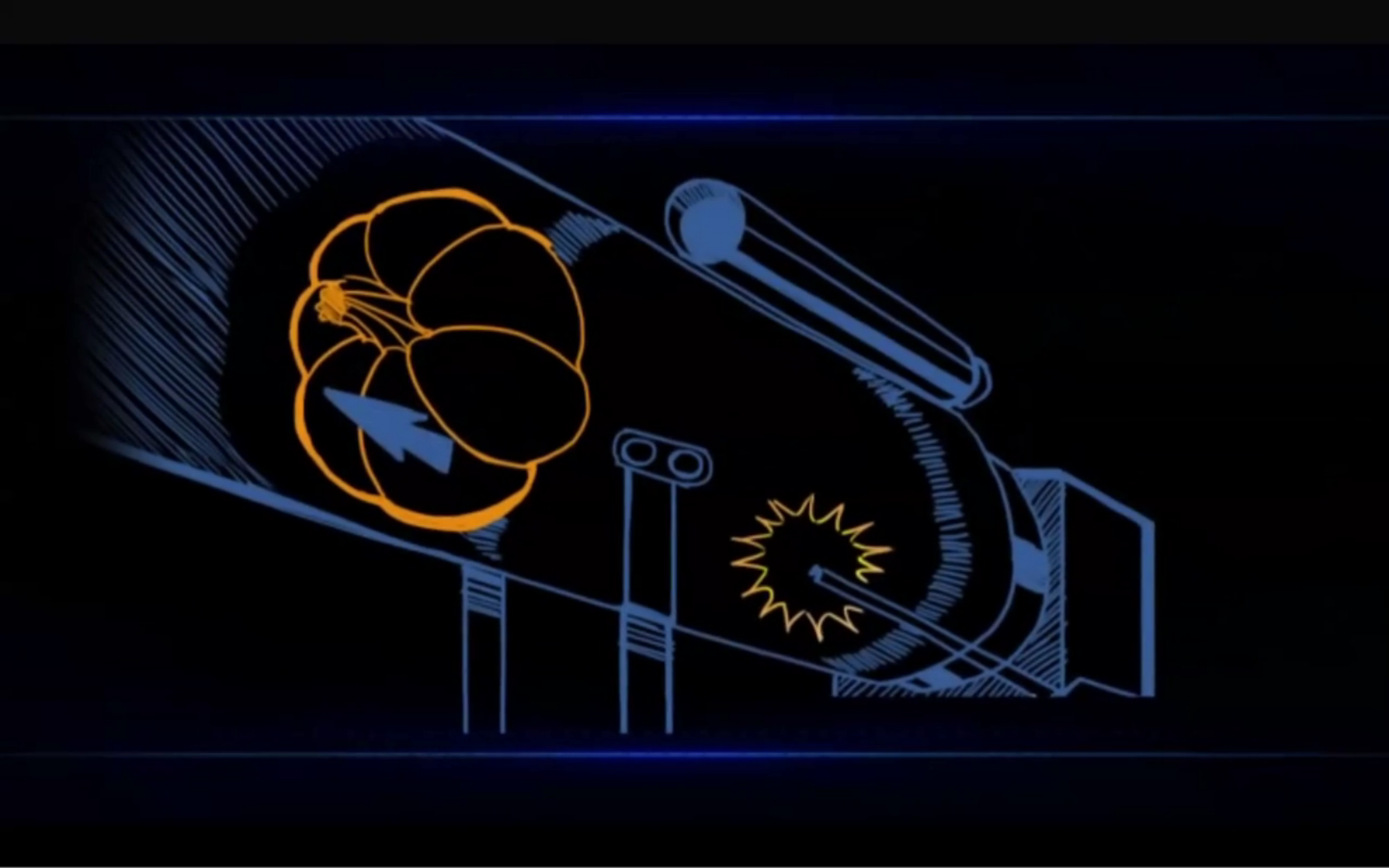

How Those Crazy Punkin Chunkin Machines Work – Cannons, Trebuchets, Centrifugals and Onagers – Behind the Chunk!

Part of hosting the Science Channel coverage of the 2009 Punkin Chunkin World Championships with Zach Selwyn means I get to do a few web videos to explain the ins-and-outs of how the amazing machines at the event work. These web spots are called…

Trebuchet Calculator Tool – Model your Pumpkin Launching Design for Maximum Distance

Super cool program: Trebstar, a Mac and PC trebuchet modeling software, calculates the range and efficiency of your trebuchet design. The program has various configurable parameters and animations, and also shows the forces on the different components of the trebuchet itself – lets you…

Homemade Pumpkin-Launching Catapult That Shoots 2000 feet – Punkin’ Chunkin’

Looking for pumpkin catapult/trebuchet plans? Check out my roundup of online trebuchet plans here. I’m hosting the 2009 Punkin Chunkin competition alongside my Catch It Keep It pal Zach Selwyn. During the preliminary filming, we stopped to visit with “Sir Chunks A Lot” — a team…