Template for the Temporary Brick Pizza Oven Arch, How to Determine the Radius of an Arch, and Removing the Jig

The temporary brick pizza oven I helped build got a lot of attention and a number of questions about the jig used to place the bricks into the arch. Here are the details and a rough blueprint: -Legs: 2×4, approximately 12″ long (extending 9.25″…

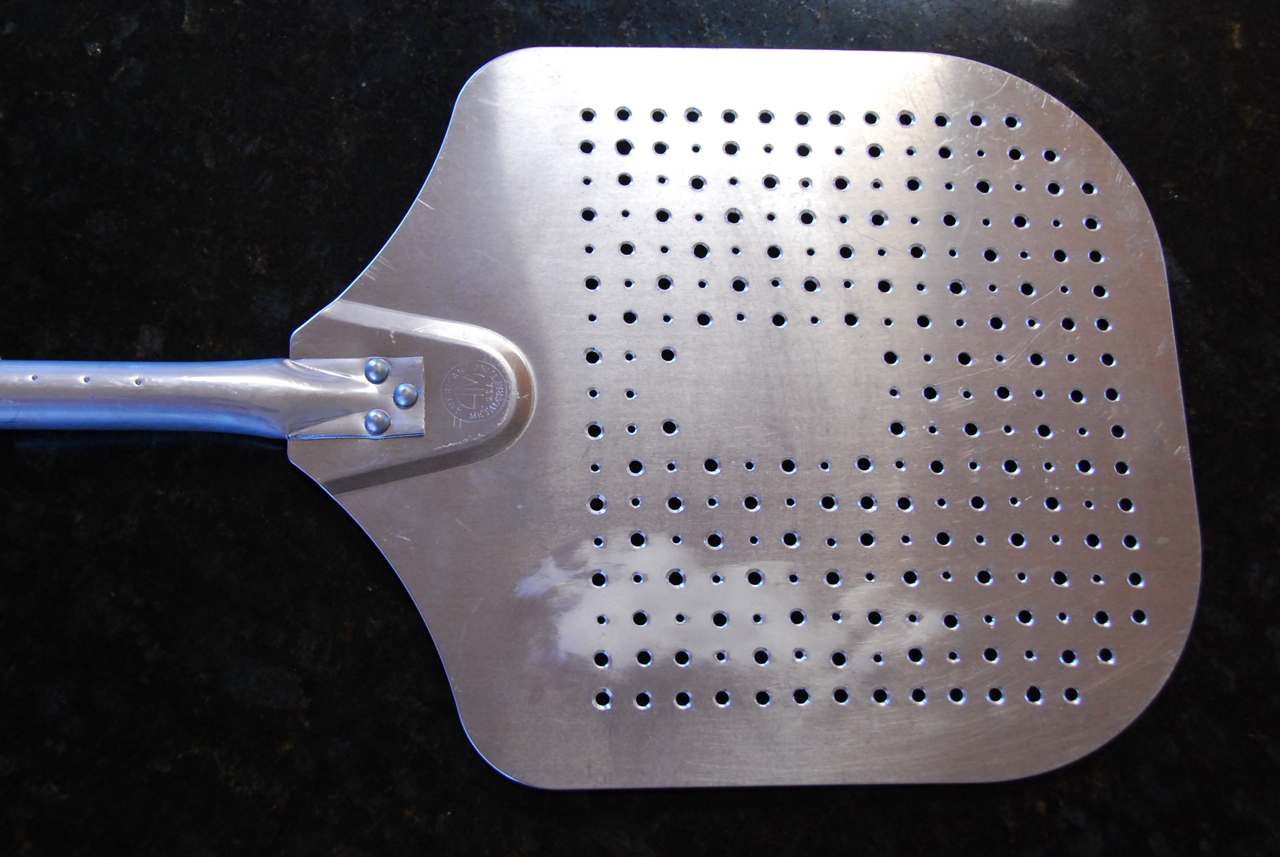

Make a Perforated Pizza Peel for Improved Pizza Making

After getting to use Pizzahacker’s perforated pizza peel, I decided to make a DIY version for myself. The idea behind a perforated peel is that it reduces the amount of flour that gets underneath the dough when placing it in the oven (too much…

Wood Fired Pizza On the PizzaForge BBQ Oven with PizzaHacker

Jeff Krupman (aka PizzaHacker) is doing some very cool things in the pizza world. His oven, dubbed the PizzaForge (formerly called the FrankenWeber) is a true wood-fired pizza cooker that is ingeniously built onto a ubiquitous Weber 22.5″ grill. Even better than having designed…

Quick and Easy Way To Clean Your Pizza Stone: Power Sander

Pizza stones tend to get dirty quickly – spill some sauce or cheese onto the 600ºF surface and it almost immediately turns into a burnt black mess. I usually clean my stone passively, scraping any excessive residue with a dough scraper and letting the…

If You Can Cut and Fold Paper, You Can Make These Papercraft Pizza Toys

Another fun project to sneak in at the end of a slow day in the office: Pizza Papercraft Print these pizza-based papercraft templates out (use the color laser printer to really make them sparkle), cut as indicated (an exacto knife and the metal ruler…

Free LED Flashlight at Harbor Freight

UPDATE: You can find an active coupon for this deal on the Harbor Freight website. Good from April 15 to May 16, 2010. Just saw this last night – print this coupon out, bring it to your nearest Harbor Freight tools and get a free…

Pizza Photo Gallery: 36 Pizzas I’ve Made (and Sourdough Crust Info)

Hey pizzaphoto readers: If you like photos of pizza, make sure to follow me on twitter here. Pizza: One of my favorite things to make. There are so many challenging variables in creating a perfect pizza, many that are nearly impossible to control completely….

A Rundown of The Top DO IT Posts For Your Weekend DIY Inspiration

Jump into your weekend with some DIY projects. Here are a few of my favorite ones that I’ve posted here. Remember to take pics and send them to me too. How to Build a Temporary Wood-fired Brick Pizza Oven with Cheap, Easy to Find…

What My NY Pizzeria Safari Taught Me About Making Pizza

As a pizza making fanatic, I love visiting well-regarded pizzerias to observe and sample their handiwork, learn some tips, and gather inspiration. During my recent travels to New York City, I set out on a pilgrimage to eat at some of the top pizza on…

Make Your Own Wooden Pizza Peel (Paddle)

A pizza peel (that’s the proper name) is a must-have tool for any pizza chef. Most of the wooden peels you’ll find in the restaurants and stores have a wide paddle area with a simple tapered edge, extending about 3/4″ around the perimeter, top…