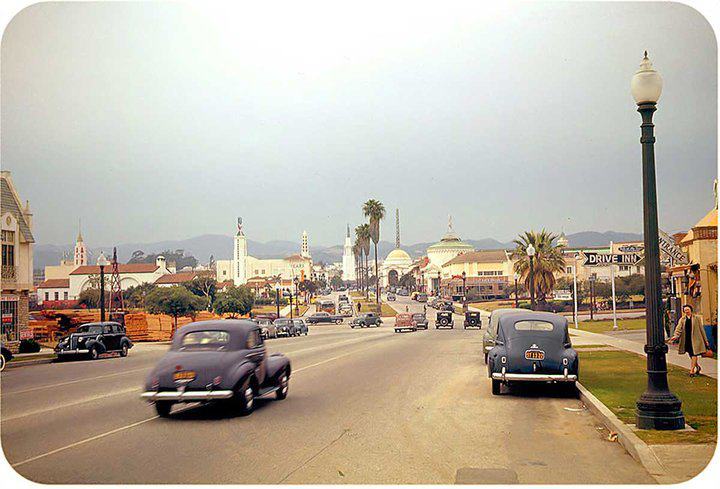

Westwood Village – The Mos Eisley of the 1940s?

Domes, towers and spires – something felt familiar about the above photo of Westwood, circa 1940. And then it hit me: Mos Eisley, the wild spaceport that hides some of the biggest scourges in the galaxy. Twin cities, separated at birth.

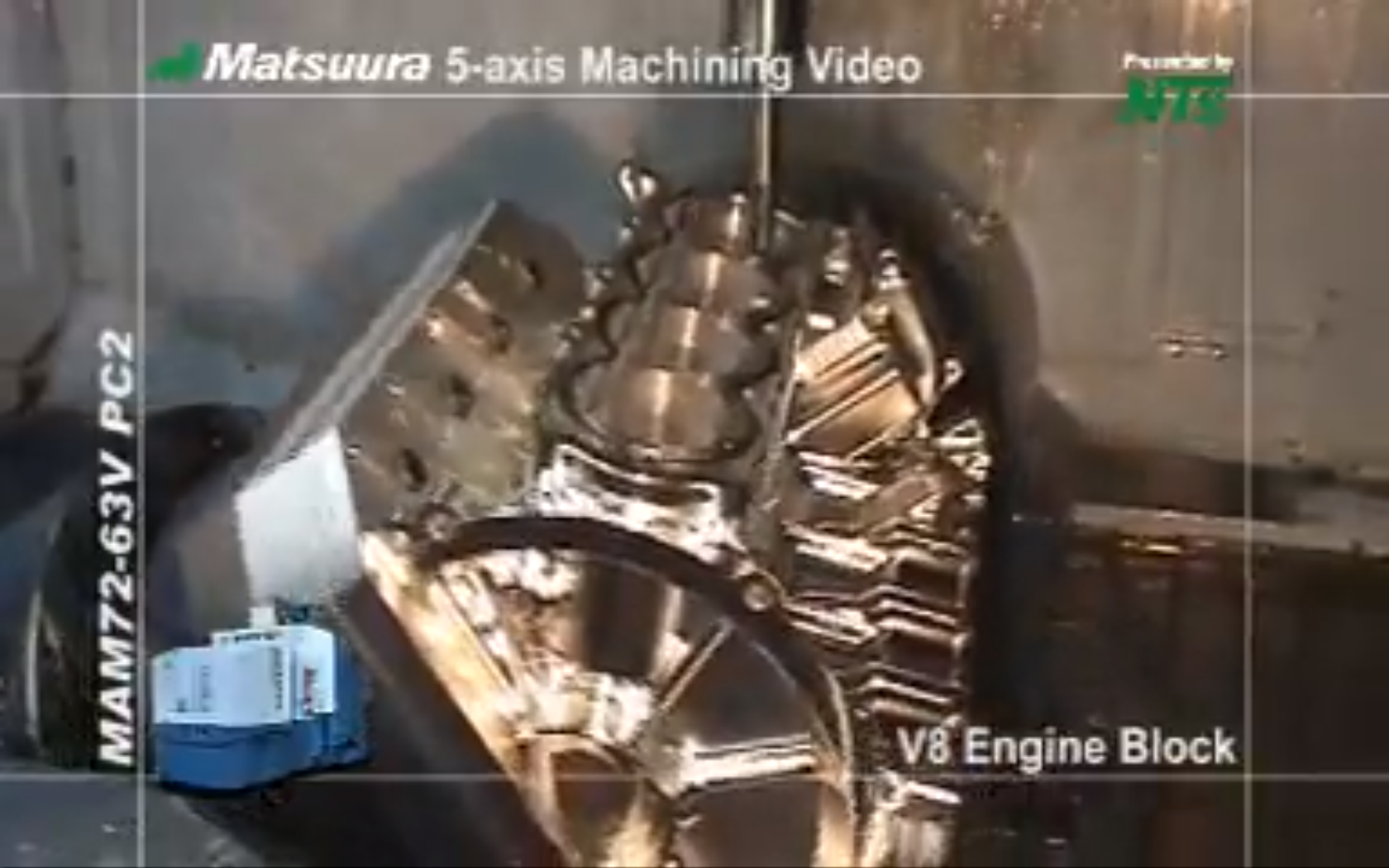

Video Fun: V8 Engine Block Machined From Solid Aluminum on a 5-Axis CNC Mill

Just a little something to fall asleep to tonight.

Five Years Ago: The Dramatic and Devastating Oakland Freeway Tanker Fire And Collapse

Hard to believe that it’s been half a decade since the early-morning tanker crash and ensuing fire on the Macarthur freeway exchange in Oakland. The devastation was fast and intense — the entire overpass melted into a Dali-esque mess of withered steel and draping asphalt. Amazingly, builders were able to repair the overpass in just 26 days.

Darth Vader, Sans Cape and Helmet, Looks Like a Leather Gimp Slave From the Local Goth Club

What’s this? A beat-up old Star Wars toy

Why is it cool? It’s the large-size model (15″), not as common as the small figurines, and because of missing pieces it looks more like C3P0’s dad than Luke’s.

What’s the story? In 1977, people had no idea what a massive mark Star Wars would leave on their generation. Sci-fi was a bit of a niche area in film, and the concept of a summer blockbuster didn’t even exist yet. But the movie’s small, 32-theater opening created a massive buzz, and led to a nationwide unrolling. Crowds of people lined up to spend a couple hours in a galaxy far, far away — a tradition they’ve been doing at every theatrical release of the franchise ever since.

17 Photos From Caine’s Arcade, his Cardboard Games and his $150,000 Cardboard Check

What is this? A genius-level DIY game arcade that will make you start hoarding cardboard boxes

Who made it? Nine year old Caine Monroy from East LA

Awesome element: The brilliance of the Fun Pass — a representation of a child’s game-play dreams, and a shrewd business move all in one.

What’s the story? Caine Monroy is a nine year old with a passion for carnival-style games so deep that he built his own arcade using the resources around him: cardboard boxes from his dad’s used auto parts business. Set in a tougher part of Los Angeles, his fully-operational/fully-adorable arcade got no customers until the day Nirvan Mullick stopped by while looking for a car part and spotted the genius that this kid radiates. Nirvan subsequently produced a 10 minute documentary about Caine and his arcade, and built a website to help raise funds for Caine’s college tuition fund. A very warmly told tale, the story made the news on every major outlet by the end fo the week it was launched. I highly recommend you watch his video if you haven’t yet seen it.

DIY Motorized Router Table Lift Mechanism and Two Other Innovative Router Tables

A router is a versatile and useful tool, although a pretty crazy one too. It’s a compact, high-powered motor that holds a narrow cylindrical blade (“bit”), spinning at ultra-high speeds with massive force. Routers are used for ornamental design work (look at the recessed borders cut into your cabinet doors — that’s routed) and cutting material. A variety of bit shapes allow for different contours of cuts — straight, angled, curved, curved with a protruding angle, etc.

Succulent Planter Made From A Wooden Carpenter’s Toolbox

I’ve had a countertop of succulents that needed a permanent home for some time now, and had been hoping to put them in a wooden box with rustic charm. Last weekend I stopped at my local Orchard Supply for supplies and saw a cheap tool set that included a wooden box with the classic OSH logo on it. For $20, it included a hammer, flathead and phillips screw drivers, tape measure, small level, and kids-sized safety goggles. Handy stuff for a kitchen drawer, but I had other thoughts for small carpenter’s tool box.

With Respect to The Terrifying, Truck-Throwing Texas Tornado, Here’s a Video of a Moving Train Being Toppled By a Twister

Earlier this week a batch of giant tornados criss-crossed the Dallas-Ft. Worth region, making news for the startling footage of 30,000 pound big rig trailers getting flung through the air like pieces of paper. Shocking photos and images, and a reminder of how intense the power of nature can be. Fortunately, no deaths have been reported.

Want to See a Half-Mile High Dust Devil on Mars?

Interesting video on Weather Channel’s website that shows an aerial image of a 1/2 mile tall, 100 foot wide dust devil sweeping the sandy martian plains. The resolution of the satellite image is pretty amazing, and allows researchers the ability to calculate the twister’s dimensions based on the length of the shadow it cast (and knowing the angle of the sun at the moment the shot was taken.)

Six of the Geekiest RC Quadrotor and Flying Designs: “Back to the Future” Flying DeLorean, X-Wing Fighter, and More

RC quadrotors (or quadcopters) have so much awesome potential because they are basically stable, powerful floating platforms, capable of a variety flight-enabled projects. You can mount a camera on one to capture amazing aerial video, or create a menacing autonomous surveillance system. Or — on the far end of geekiness — you can dress one up in costume, and fly your nerdiest world of fandom through the sky for all to see, like these following guys have done: